ASTM A387 F5/ASTM Grade 5Plate & Sheet, Cold Roll Strip, Cold Roll sheet, Cold Rolled coil

SAE A 958 Grade SC 1030 Class 70/36 ( Precipitation-Hardening )

-

SAE A 958 Grade SC 1030 Class 70/36 Details

SAE standard material A 958 Grade SC 1030 Class 70/36 belongs to the USA, from the steel to the finished product, we have the perfect technology and many years of accumulation of experience, we can now produce products include steel coil, sheet, plate,round bar, square steel, steel wire, steel pipe, forgings, other...

A 958 Grade SC 1030 Class 70/36 Application:Standard Specification for Steel Castings, Carbon and Alloy, with Tensile Requirements, Chemical Requirements Similar to Standard Wrought Grades

| Elements | Min.(≥) | Max.(≤) | Similar | Remarks |

|---|---|---|---|---|

| C | - | 0.15 | ||

| Si | - | 1.00 | ||

| Mn | 3.75 | 4.75 | ||

| P | - | 0.045 | ||

| S | - | 0.03 | ||

| Ni | 9.00 | 10.50 | ||

| Cr | 19.00 | 22.00 | ||

| Al | - | - | ||

| Cu | - | - | ||

| Ti | - | - | ||

| Fe | - | - | ||

| N | - | - | ||

| Mo | - | - | ||

| V | - | - |

| Yield Rp0.2 (MPa) |

Tensile Rm (MPa) |

Impact KV (J) |

Elongation A (%) |

Reduction in cross section on fracture Z (%) |

As-Heat-Treated Condition | HBW |

|---|---|---|---|---|---|---|

| 542 (≥) | 218 (≥) | 11 | 11 | 41 | Solution and Aging, Annealing, Ausaging, Q+T,etc | 242 |

| Property | Density kg/dm3 |

Temperature T °C/F |

Specific heat J / kgK |

Thermal conductivity W/mK |

Electric resistance µΩ·cm |

|---|---|---|---|---|---|

| 729 (≥) | 844 (≥) | 21 | 23 | 34 | Solution and Aging, Annealing, Ausaging, Q+T,etc |

| Temp. °C/°F |

Creep strain limit (10000h) (Rp1,0) N/mm2 |

Creep rupture strength (10000h) (Rp1,0) N/mm2 |

- | - | - |

| 297 | 181 | 627 | - | - | - |

| Product type | Products | Dimension | Processes | Deliver Status |

|---|---|---|---|---|

| Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

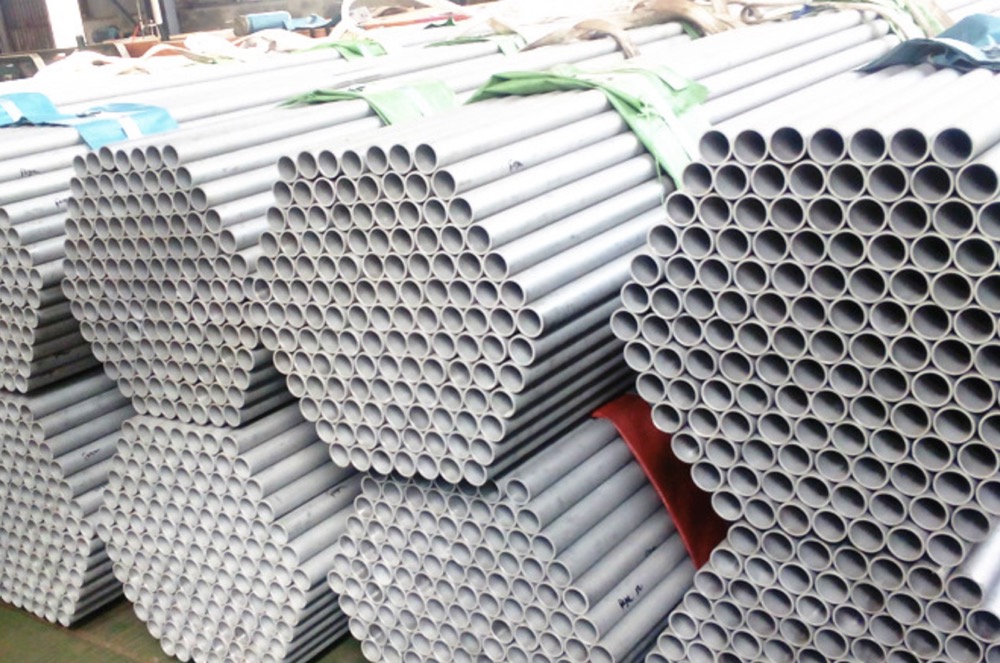

| Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

-

Equivalent Grade

A 307 Grade A | A 307 Grade B | A 307 Grade C | A 958 Grade SC 1030 Class 70/36 | A 958 Grade SC 4130 Class 70/36 | A 958 Grade SC 4330 Class 70/36 | A 958 Grade SC 8630 Class 70/36 | B 30 70C | B 30 72C | B 30 7A | B 774 307-323 | B860 Z30750 | E 307 | E 307 | E307T | E307T | E307T0-3 | E307T0-3 | ER 307 | ER 307 | -

Standard No.

- USA - SAE - A 958/A 958M (2010)

Standard Specification for ...

- USA - SAE - A 958/A 958M (2010)

-

Relevant products

-

Machinability

- Machinability

-

Heat Treatment

- Heat Treatment